- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SPZ1270-1670FHE

FANGYUAN

New type FHE series eps shape molding machine with manipulator

Due to the application of flexible compound drive technology, the equipment can realize quick mold-opening/closing (4 times faster than that of hydraulic drive) and free servo drive, eliminate the hydraulic drive noise, reduce oil stain generated during replacement of hydraulic oil and prolong the service life.

By means of the mature and reliable servo control system, the manipulator can realize excellent mold-opening/closing cooperativity, stable operation, convenient position adjustment due to graphic parameter setting and high seam accuracy for mold closing.

Standardized one-key mold clamping simplifies the mold assembly process, reduces mold processing accuracy, and lowers mold opening costs.

Reliable industrial personal computer, with multiple Ethernet interfaces, provides the necessary guarantee for modern smart factory networking. Application of integrated valve terminal bus, Convenient for use and maintenance.

Multiple heat insulation measures for the air chamber, optimized pipeline design, non-rubber tube air chamber The heating speed can be improved by 30% due to optimized pipe capacity and less pipe loss, greatly reducing the steam energy consumption.

Seamless mold connection technology and automatic & seamless connection technology for material disposal that has won multiple national patents.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able sales

staff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

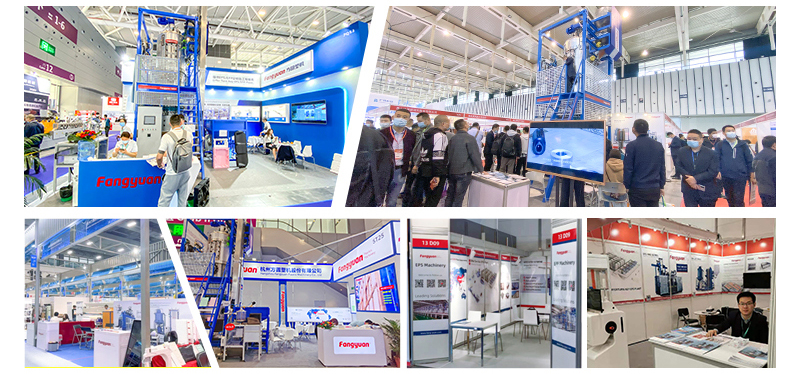

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales and

service delivery, provides our clients with system solutions including design, training, operation

and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,

resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

100,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

New type FHE series eps shape molding machine with manipulator

Due to the application of flexible compound drive technology, the equipment can realize quick mold-opening/closing (4 times faster than that of hydraulic drive) and free servo drive, eliminate the hydraulic drive noise, reduce oil stain generated during replacement of hydraulic oil and prolong the service life.

By means of the mature and reliable servo control system, the manipulator can realize excellent mold-opening/closing cooperativity, stable operation, convenient position adjustment due to graphic parameter setting and high seam accuracy for mold closing.

Standardized one-key mold clamping simplifies the mold assembly process, reduces mold processing accuracy, and lowers mold opening costs.

Reliable industrial personal computer, with multiple Ethernet interfaces, provides the necessary guarantee for modern smart factory networking. Application of integrated valve terminal bus, Convenient for use and maintenance.

Multiple heat insulation measures for the air chamber, optimized pipeline design, non-rubber tube air chamber The heating speed can be improved by 30% due to optimized pipe capacity and less pipe loss, greatly reducing the steam energy consumption.

Seamless mold connection technology and automatic & seamless connection technology for material disposal that has won multiple national patents.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able sales

staff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

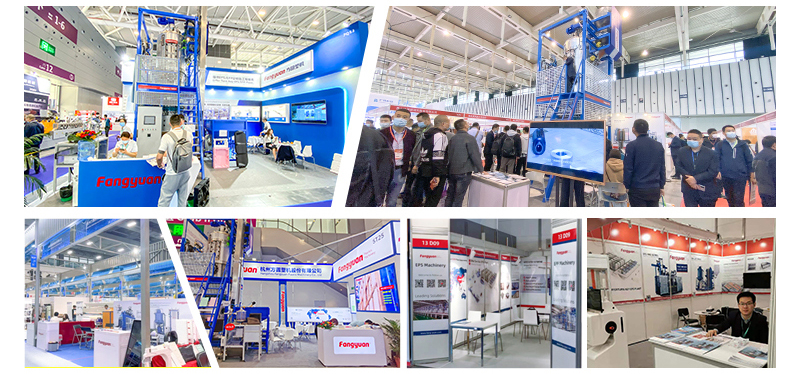

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales and

service delivery, provides our clients with system solutions including design, training, operation

and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,

resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

100,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow