- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SPZ140TE

FANGYUAN

Main Features:

1.With high-rigid structure, thickness of forms in this expanded polystyrene foam machine is 50mm larger than that of forms in ordinary machine, and the diameter is φ85. An integrated structure is adopted for the auxiliary load-bearing guide rail, expanded polystyrene foam machine feet and guide rail base are welded to each other, being shaped in single process, resulting in excellent load bearing capacity.

2.With pipeline of larger size, the application of patented impulse steam valve of DN100 flow rate guarantees the speed of heating.

3.Cutting-edge vacuum mode allows products to cool down very quickly, which can reduce water consumption and increase production efficiency.

4.Combination of ways of expanded polystyrene foam machine feeding and automatic eps expanded polystyrene feeding increases the speed of materials feeding, and reduces feeding time.

5.Higher running speed of hydraulic system can reduce the time of mechanical operation.

6.The expanded polystyrene foam machine is equipped with photoelectric safety device; when the light curtain is covered, the device sends out light covering signal, which will shut down the equipment with potential risks, and avoid any possible safety accident.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

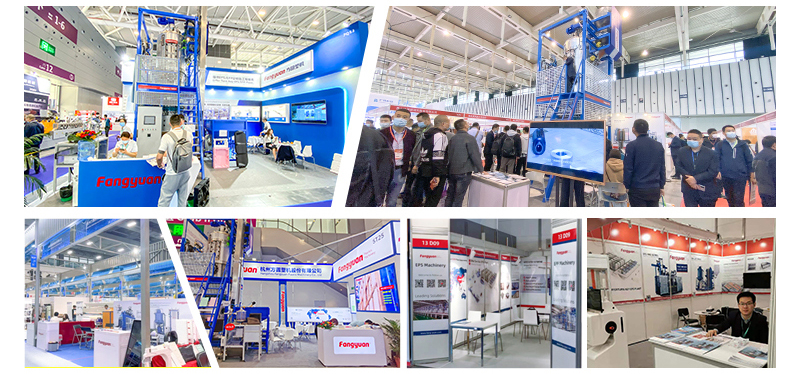

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

Main Features:

1.With high-rigid structure, thickness of forms in this expanded polystyrene foam machine is 50mm larger than that of forms in ordinary machine, and the diameter is φ85. An integrated structure is adopted for the auxiliary load-bearing guide rail, expanded polystyrene foam machine feet and guide rail base are welded to each other, being shaped in single process, resulting in excellent load bearing capacity.

2.With pipeline of larger size, the application of patented impulse steam valve of DN100 flow rate guarantees the speed of heating.

3.Cutting-edge vacuum mode allows products to cool down very quickly, which can reduce water consumption and increase production efficiency.

4.Combination of ways of expanded polystyrene foam machine feeding and automatic eps expanded polystyrene feeding increases the speed of materials feeding, and reduces feeding time.

5.Higher running speed of hydraulic system can reduce the time of mechanical operation.

6.The expanded polystyrene foam machine is equipped with photoelectric safety device; when the light curtain is covered, the device sends out light covering signal, which will shut down the equipment with potential risks, and avoid any possible safety accident.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

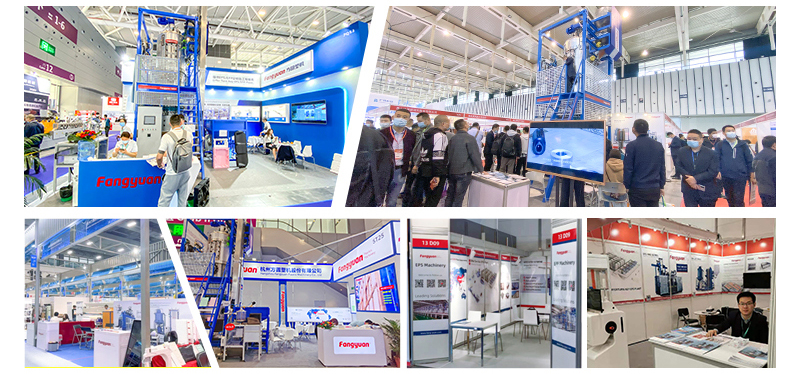

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow