- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

1018ETPU-e

FANG YUAN

Main Features:

•8 pairs of boost soles in one time of molding.

•Adjustable sole mold frame equipped: 420×420/420×380/410×365mm.

•Distinctive single-mold cooling system,with individual cooling water pipes for fixed and movable molds

in each set, thus bringing more uniform and efficient cooling performance.

•Dual-channel steam system for an energy-saving and accurate pressurization performance with high

-frequency DA+OI precise control.

•Main and auxiliary drain valves equipped to save stream and reduce unnecessary waste.

•Distinct feeding method to ensure a fast feeding speed, guarantee a high yield rate and solve the feeding

difficulty.

•All-digital display to enable precise energy consumption of steam and controllable manufacturing manage

-ment, and bring an easier and more intelligent experience.

•Inheriting all the features of the 1018ETPU model.

•Due to the application of flexible compound drive technology, the equipment can realize quick mold-opening/closing (4 times faster than that of hydraulic drive) and free servo drive, eliminate the hydraulic drive noise, reduce oil stain generated during replacement of hydraulic oil and prolong the service life.

•By means of the mature and reliable servo control system, stable operation, convenient position adjustment due to graphic parameter setting and high seam accuracy for mold closing.

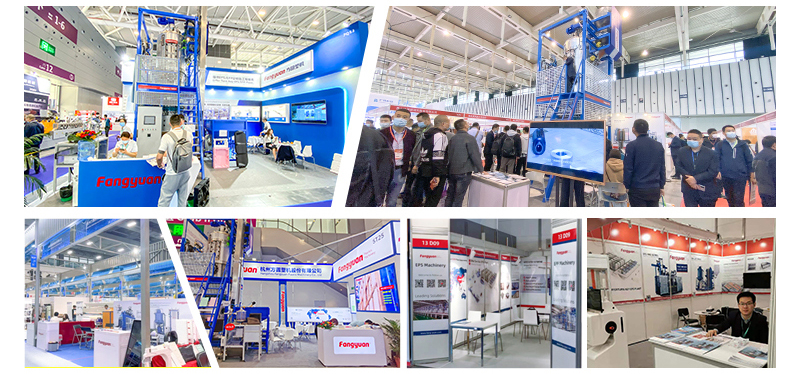

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

Main Features:

•8 pairs of boost soles in one time of molding.

•Adjustable sole mold frame equipped: 420×420/420×380/410×365mm.

•Distinctive single-mold cooling system,with individual cooling water pipes for fixed and movable molds

in each set, thus bringing more uniform and efficient cooling performance.

•Dual-channel steam system for an energy-saving and accurate pressurization performance with high

-frequency DA+OI precise control.

•Main and auxiliary drain valves equipped to save stream and reduce unnecessary waste.

•Distinct feeding method to ensure a fast feeding speed, guarantee a high yield rate and solve the feeding

difficulty.

•All-digital display to enable precise energy consumption of steam and controllable manufacturing manage

-ment, and bring an easier and more intelligent experience.

•Inheriting all the features of the 1018ETPU model.

•Due to the application of flexible compound drive technology, the equipment can realize quick mold-opening/closing (4 times faster than that of hydraulic drive) and free servo drive, eliminate the hydraulic drive noise, reduce oil stain generated during replacement of hydraulic oil and prolong the service life.

•By means of the mature and reliable servo control system, stable operation, convenient position adjustment due to graphic parameter setting and high seam accuracy for mold closing.

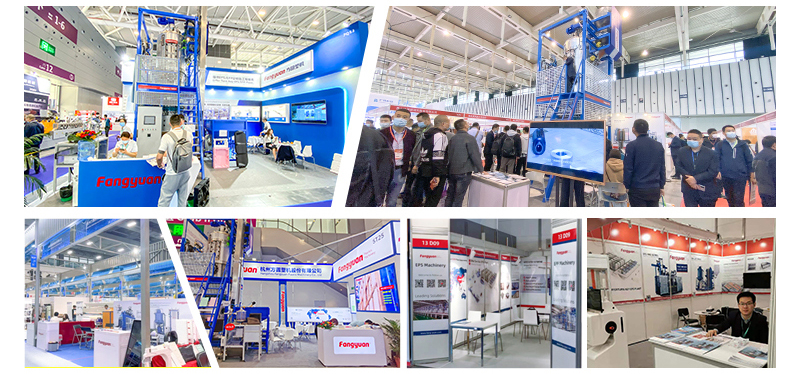

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow