- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

SPB360LZP

FANG YUAN

SPB360LZP Fireproofing Insualtion EPS Foam Board Machine

Main Features:

1. Apply vertical sliding door structure.

2. Apply multi-valve heating system to achieve more accurate, faster, more energy efficient heating process.

3. Inlet of steam for heating is located at upper part, and blow-off outlet is located at lower part of the board molding machine, with fast heating speed, good board molding effect.

4. It has automatic mixing and de-dusting, foam raw material weighing functions.

5. Sizes of board mold cavity are compressible.

6.Optimized hydraulic design can achieve rapid mold closing and opening, and products are released from molds with cylinders simultaneously.

7. It applies snap-on stainless steel permeable plate structure, easy for replacement, and steam channels are easy for cleaning;

8. Special vacuum cooling system, with good vacuum effect and rapid cooling speed;

9. Inlet valves and blow-off valves of platen are German butterfly valves

10. The steam system has a steam separator, and is equipped with relief valve at inlet;

11. Board machine control applies automatic feedback of sensors to realize intelligent, fully automated control;

12. Products are weighed and delivered to drying system automatically.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

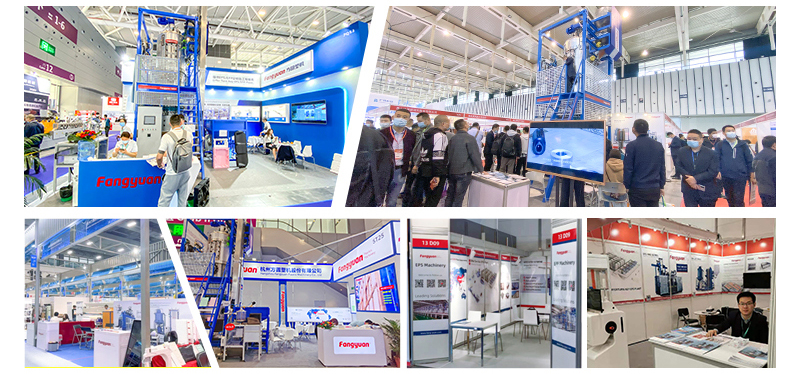

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

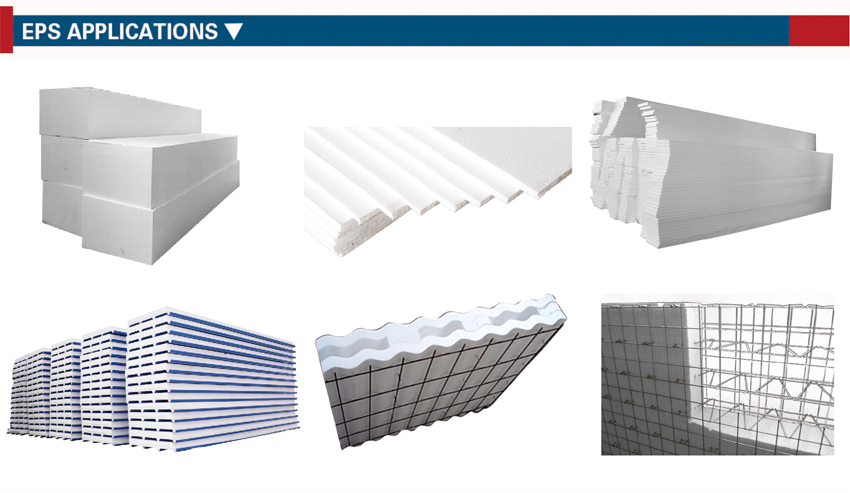

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts.

Welcome to follow

SPB360LZP Fireproofing Insualtion EPS Foam Board Machine

Main Features:

1. Apply vertical sliding door structure.

2. Apply multi-valve heating system to achieve more accurate, faster, more energy efficient heating process.

3. Inlet of steam for heating is located at upper part, and blow-off outlet is located at lower part of the board molding machine, with fast heating speed, good board molding effect.

4. It has automatic mixing and de-dusting, foam raw material weighing functions.

5. Sizes of board mold cavity are compressible.

6.Optimized hydraulic design can achieve rapid mold closing and opening, and products are released from molds with cylinders simultaneously.

7. It applies snap-on stainless steel permeable plate structure, easy for replacement, and steam channels are easy for cleaning;

8. Special vacuum cooling system, with good vacuum effect and rapid cooling speed;

9. Inlet valves and blow-off valves of platen are German butterfly valves

10. The steam system has a steam separator, and is equipped with relief valve at inlet;

11. Board machine control applies automatic feedback of sensors to realize intelligent, fully automated control;

12. Products are weighed and delivered to drying system automatically.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts.

Welcome to follow