- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

SPZ100-200T

FANG YUAN

Product Description

Key Features:

This type of EPS Foam Dome House Shape Molding Machine offers several enhancements over the standard shape molding machine, and its features include the following.

1. Machine structure:

a. The entire frame of the vacuum automatic molding machine is welded onto a 16/20mm steel plate, supported by sturdy machine legs. This significantly enhances the strength of the polystyrene molding machine.

b. The high machine legs are constructed using robust "H" type profiles, making it effortless for clients to install the EPS molding machine (only requiring floor foundation preparation).

The filling mechanism of the styrofoam molding machine uses both normal pressure and vacuum for high-pressure filling. The material filling is controlled by a level sensor with a dual rotation chamber discharge and has 44 outlets for filling.

The steam system of the EPS styrofoam molding machine utilizes a balanced PID control valve with a German gauge. This valve significantly improves the accuracy of steam and reduces consumption by approximately 20% compared to the A/B type.

The cooling system of the shape molding machine includes a large vertical tank with a powerful vacuum pump. Additionally, there is a vertical vacuum cooling water spray on top. Instead of relying solely on water cooling (typically set up for only 8-12 seconds), the EPS molding machine primarily uses vacuum cooling. This method ensures that the water content of the product remains below 10%.

Drainage system: The polystyrene automatic molding machine now has larger inlets and outlets for the mold, allowing for faster cycle times. The steam is now fed through 8-1" inlets, while the drainage system has 6/8-2" outlets. The drainage pipe is controlled by a butterfly valve, resulting in improved heating and drainage speed.

Control system:

a. The EPS automatic molding machine now features a user-friendly operation with the adoption of PLC (Mitsubishi) and touch screen (Schneider).

b. All the electronic components used in the styrofoam molding machine are sourced from reputable brands, ensuring better stability.

c. The air cooling, steam, demolding, and pressure of filling in the polystyrene molding machine are now controlled by a long-distance balance valve.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

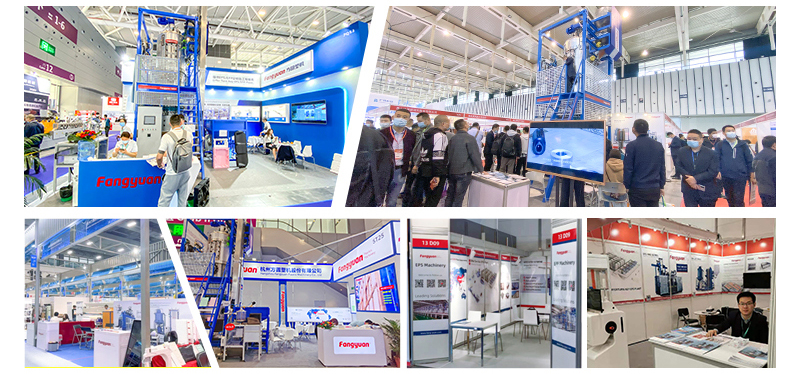

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

Product Description

Key Features:

This type of EPS Foam Dome House Shape Molding Machine offers several enhancements over the standard shape molding machine, and its features include the following.

1. Machine structure:

a. The entire frame of the vacuum automatic molding machine is welded onto a 16/20mm steel plate, supported by sturdy machine legs. This significantly enhances the strength of the polystyrene molding machine.

b. The high machine legs are constructed using robust "H" type profiles, making it effortless for clients to install the EPS molding machine (only requiring floor foundation preparation).

The filling mechanism of the styrofoam molding machine uses both normal pressure and vacuum for high-pressure filling. The material filling is controlled by a level sensor with a dual rotation chamber discharge and has 44 outlets for filling.

The steam system of the EPS styrofoam molding machine utilizes a balanced PID control valve with a German gauge. This valve significantly improves the accuracy of steam and reduces consumption by approximately 20% compared to the A/B type.

The cooling system of the shape molding machine includes a large vertical tank with a powerful vacuum pump. Additionally, there is a vertical vacuum cooling water spray on top. Instead of relying solely on water cooling (typically set up for only 8-12 seconds), the EPS molding machine primarily uses vacuum cooling. This method ensures that the water content of the product remains below 10%.

Drainage system: The polystyrene automatic molding machine now has larger inlets and outlets for the mold, allowing for faster cycle times. The steam is now fed through 8-1" inlets, while the drainage system has 6/8-2" outlets. The drainage pipe is controlled by a butterfly valve, resulting in improved heating and drainage speed.

Control system:

a. The EPS automatic molding machine now features a user-friendly operation with the adoption of PLC (Mitsubishi) and touch screen (Schneider).

b. All the electronic components used in the styrofoam molding machine are sourced from reputable brands, ensuring better stability.

c. The air cooling, steam, demolding, and pressure of filling in the polystyrene molding machine are now controlled by a long-distance balance valve.

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow