- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

FANG YUAN

Customizable Aluminum Mould for EPS Foam Box Production

Introduction

Fangyuan’s mould branch has over 100 staff, with more than 20 engineers and technicians. With the help of CAD/UG/PRO E for EPS plastic mold design and manufacturing, using CAM programming process, adopting AutoCAD/2000 two-dimensional design the drawings, with 10 high-end CNC process machining Centers and nearly 30 general mould machining equipment. The EPS moulding machine is one of the best products.

Main Features of the styrofoam moulding machine

Fangyuan’s mould branch specialized in all kinds of EPS、EPP moulds for styrofoam shape aluminum moulding machine and retractable mould for thermocol shape aluminum moulding machine and EPP machine. The 6063 high-quality aluminum alloy material is used for machines of various types, and design with standard mould chamber and standard cooling system. The shape molding machine surface is sprayed with protective Teflon coating with features of excellent lubrication, no sticking on the mould, convenient de-mould. The EPS shape moulding machine also has good anti-corrosion and can resistant to high-temperatures of above 350℃. Our mould such as the polystyrene molding machine can service for you for a long time. As a professional mould manufacturer, we will provide you high-quality EPS foam mould and service, so contact us for details now!

Design Mould Maker CNC Processing Assembly Checking

EPS Mould And Accessories

Mould Core Mould Cavity

Filling Gun Ejector

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

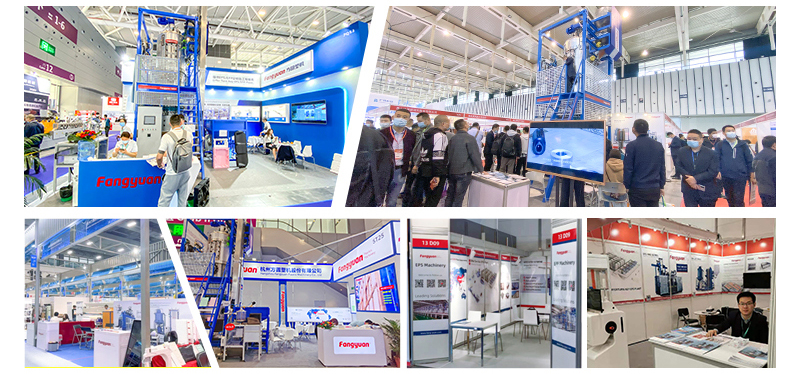

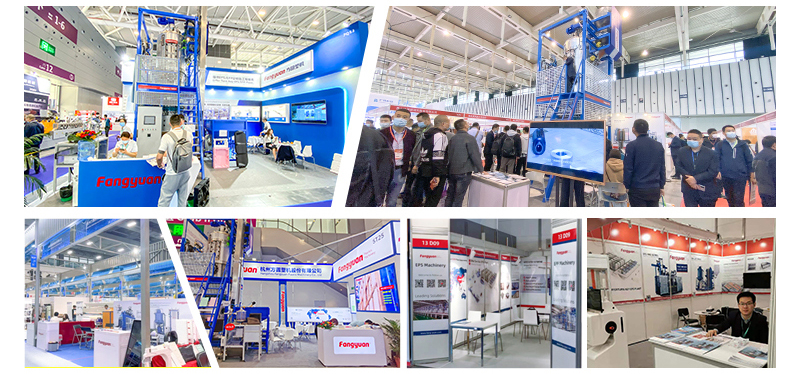

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow

Customizable Aluminum Mould for EPS Foam Box Production

Introduction

Fangyuan’s mould branch has over 100 staff, with more than 20 engineers and technicians. With the help of CAD/UG/PRO E for EPS plastic mold design and manufacturing, using CAM programming process, adopting AutoCAD/2000 two-dimensional design the drawings, with 10 high-end CNC process machining Centers and nearly 30 general mould machining equipment. The EPS moulding machine is one of the best products.

Main Features of the styrofoam moulding machine

Fangyuan’s mould branch specialized in all kinds of EPS、EPP moulds for styrofoam shape aluminum moulding machine and retractable mould for thermocol shape aluminum moulding machine and EPP machine. The 6063 high-quality aluminum alloy material is used for machines of various types, and design with standard mould chamber and standard cooling system. The shape molding machine surface is sprayed with protective Teflon coating with features of excellent lubrication, no sticking on the mould, convenient de-mould. The EPS shape moulding machine also has good anti-corrosion and can resistant to high-temperatures of above 350℃. Our mould such as the polystyrene molding machine can service for you for a long time. As a professional mould manufacturer, we will provide you high-quality EPS foam mould and service, so contact us for details now!

Design Mould Maker CNC Processing Assembly Checking

EPS Mould And Accessories

Mould Core Mould Cavity

Filling Gun Ejector

We do have a qualified group of English, Russian, Indian, Arabic speaking engineers and an able salesstaff that support us around the world. We set sales and service office in lndia, Iran, Syria, Egypt etc.

Founded in 1988,over 600 staff and covered 100,000 sqm Workshop.

Professional EPS, EPP, EPO, ETPU machinery manufacturer integrating R & D, production, sales andservice delivery, provides our clients with system solutions including design, training, operation and turn-key projects.

Yearly around 2,200 sets machines outputs.

Exported to more than 103 countries.

The first drafter of National lndustry Standard of EPS machinery in China.

Since 1988, More Than 50,000 Units Equipment in 103 Countries and Area.

FANGYUAN boasts a pool of fine teams, with qualified EPS/EPP products as to moulds, equipment,resources, technologies, and with rich experience at production and operation.

PRE-SALES SERVICE

Inquiry And Consulting Support

Lastest Industry Trends

Offer Turn-key EPS Plant

Sample Testing Support

View Our Factory

Suggest Layout Support

AFTER-SALES SERVICE

One Year Warranty

Machine Test Video Before Delivery

English Manual, Electric Diagram Training How To Install And Running The Machine

Engineers Available To Service Machinery Overseas

24 Hours Online Service

130,000 ㎡ Workshop.

Yearly Around 2,200 Sets Machines Outputs.

24 Hours Technical Supports and Aftersales Service.

Professional Maintenance and Offer All Kinds of Spare Parts

Welcome to follow